NY Private Fire Hydrant Maintenance Report - Town of Brighton 2013-2026 free printable template

Show details

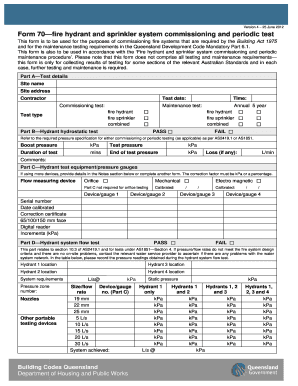

Private Fire Hydrant Maintenance Report TOWN OF BRIGHTON Office of the Fire Marshal The purpose of this Standard is to clarify the requirements for the testing inspection maintenance and marking of private fire hydrants. It is the responsibility of the property owner to have all the fire hydrants located on his/her property tested once every year in accordance with NFPA 25. 2300 Elmwood Avenue Rochester New York 14618 585 784-5220 Office 585 784-5207 Fax Address Inspection Type Date of...

pdfFiller is not affiliated with any government organization

Get, Create, Make and Sign fire hydrant inspection form

Edit your hydrant flow test report template form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your urban fire hydrant inspection form form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing fire hydrant checklist in excel online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit fire hydrant inspection checklist form. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

pdfFiller makes working with documents easier than you could ever imagine. Create an account to find out for yourself how it works!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out fire hydrant inspection report form

How to fill out NY Private Fire Hydrant Maintenance Report

01

Begin by gathering all necessary information about the fire hydrant, including its location and identification number.

02

Inspect the fire hydrant physically to ensure it is in working condition, checking for visible damage, rust, and proper visibility.

03

Record the date of the inspection and the name of the person conducting it.

04

Document any maintenance activities performed, such as lubrication or repairs.

05

Check the flow test results, if applicable, and record the flow rates observed during the test.

06

Ensure all required signatures are obtained at the end of the report from responsible parties.

07

Submit the completed report to the appropriate local authority or fire department.

Who needs NY Private Fire Hydrant Maintenance Report?

01

Property owners or managers of sites with private fire hydrants.

02

Fire safety inspectors and local fire departments for compliance and safety checks.

03

Insurance companies that may require documentation of fire safety measures.

Fill

fire hydrant report

: Try Risk Free

People Also Ask about hydrant inspection checklist

Do fire hydrants have to be emptied?

Fire hydrant flushing is necessary to ensure that adequate flow and pressure is available. Flushing also removes sediment from the distribution pipes to maintain water clarity and quality.

How are fire hydrants maintained?

Lubricate Regularly. Fire hydrants are typically greased or oiled. Follow the manufacturer's instructions on lubrication. Without proper lubrication, corrosion can occur, making the hydrant difficult—or, in some cases, impossible—to operate.

What maintenance is required for hydrant system?

Maintaining the Fire Hydrant Remove one nozzle/pumper cap and, using a listening device, check for main valve leakage. Using a plumb-bob, check the barrel for water or ice. Replace the nozzle/pumper cap, leaving it loose enough for air to escape. Open the hydrant fully, checking for ease of operation.

How do you inspect and maintain a fire hydrant?

Annual Hydrant Inspections Look for obstructions that could interfere with hydrant operation. Check for cracked or missing caps. Look for leaky or broken nozzles, gaskets, and valves. Check for the correct above-ground hydrant height. Determine if the hydrant needs to be painted. Check for main valve leaks.

How often should every hydrant be checked?

ing to NFPA 25, a fire hydrant must be inspected annually and after each operation. The flow must be tested each year and maintenance must be performed annually as well.

How often should fire hydrants be flushed?

Fire hydrants should be flushed at least annually to verify operation, address repairs, and verify reliability.

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send printable fire hydrant template to be eSigned by others?

Once your hydrant flow test form is ready, you can securely share it with recipients and collect eSignatures in a few clicks with pdfFiller. You can send a PDF by email, text message, fax, USPS mail, or notarize it online - right from your account. Create an account now and try it yourself.

How do I make changes in fire hydrant flow test report form?

The editing procedure is simple with pdfFiller. Open your payroll direct deposit authorization form in the editor, which is quite user-friendly. You may use it to blackout, redact, write, and erase text, add photos, draw arrows and lines, set sticky notes and text boxes, and much more.

How do I fill out fire hydrant monthly inspection checklist on an Android device?

On an Android device, use the pdfFiller mobile app to finish your fire hydrant printable template. The program allows you to execute all necessary document management operations, such as adding, editing, and removing text, signing, annotating, and more. You only need a smartphone and an internet connection.

What is NY Private Fire Hydrant Maintenance Report?

The NY Private Fire Hydrant Maintenance Report is a document that records the maintenance and inspection activities performed on private fire hydrants to ensure they are functioning properly and remain compliant with safety regulations.

Who is required to file NY Private Fire Hydrant Maintenance Report?

Property owners or designated representatives of buildings with private fire hydrants are required to file the NY Private Fire Hydrant Maintenance Report.

How to fill out NY Private Fire Hydrant Maintenance Report?

To fill out the NY Private Fire Hydrant Maintenance Report, property owners must provide details such as the location of the hydrant, the maintenance performed, inspection dates, and any repairs needed.

What is the purpose of NY Private Fire Hydrant Maintenance Report?

The purpose of the NY Private Fire Hydrant Maintenance Report is to ensure the proper maintenance of private fire hydrants, thereby enhancing fire safety and response capabilities.

What information must be reported on NY Private Fire Hydrant Maintenance Report?

The report must include information such as the hydrant's address, condition and functionality of the hydrant, details of maintenance performed, inspection dates, and any necessary repairs.

Fill out your NY Private Fire Hydrant Maintenance Report online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Fire Hydrant Checklist is not the form you're looking for?Search for another form here.

Keywords relevant to hydrant maintenance checklist

Related to nfpa fire hydrant inspection form

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.